P.O.P PROCESS

https://kpmtech.co.kr/enK-NP 2

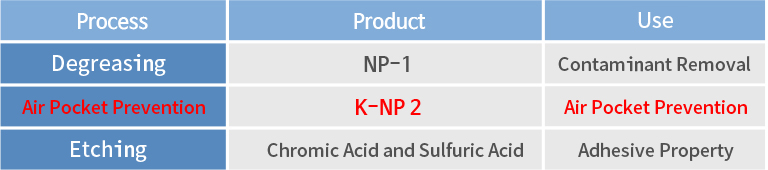

Purpose of Using K-NP 2 Surface Treatment Agent:

If, during ABS plating, air on the surface of the object being plated gets deposited in a high-temperature solution like the etching solution, that air creates pockets that can interfere with the etching process on the affected areas. Although these areas will become plated in the same manner as the other, unaffected areas due to the low surface tension of the subsequent processing solution, the affected areas will not become embossed from etching and are what cause bubbling and improper adhesion in chemical plating.

Degreasing in ABS plating differs from degreasing in standard metallic plating in that the process involves the use of a dedicated agent that does not contain silicates. These plastic-degreasing agents remove contaminants, fingerprints, and oils and fats from the surface of the object being plated to give it greater hydrophilicity and prevent the formation of air pockets.

Allowing a plastic-degreasing agent to settle for two to ten minutes at a low temperature between 50 °C and 60 °C also has an annealing effect that simultaneously eliminates surface deformation of the object being plated while enhancing the etching effect and improving adhesion.

KPM POP Process

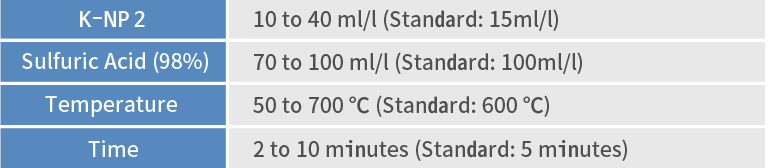

Usage Conditions